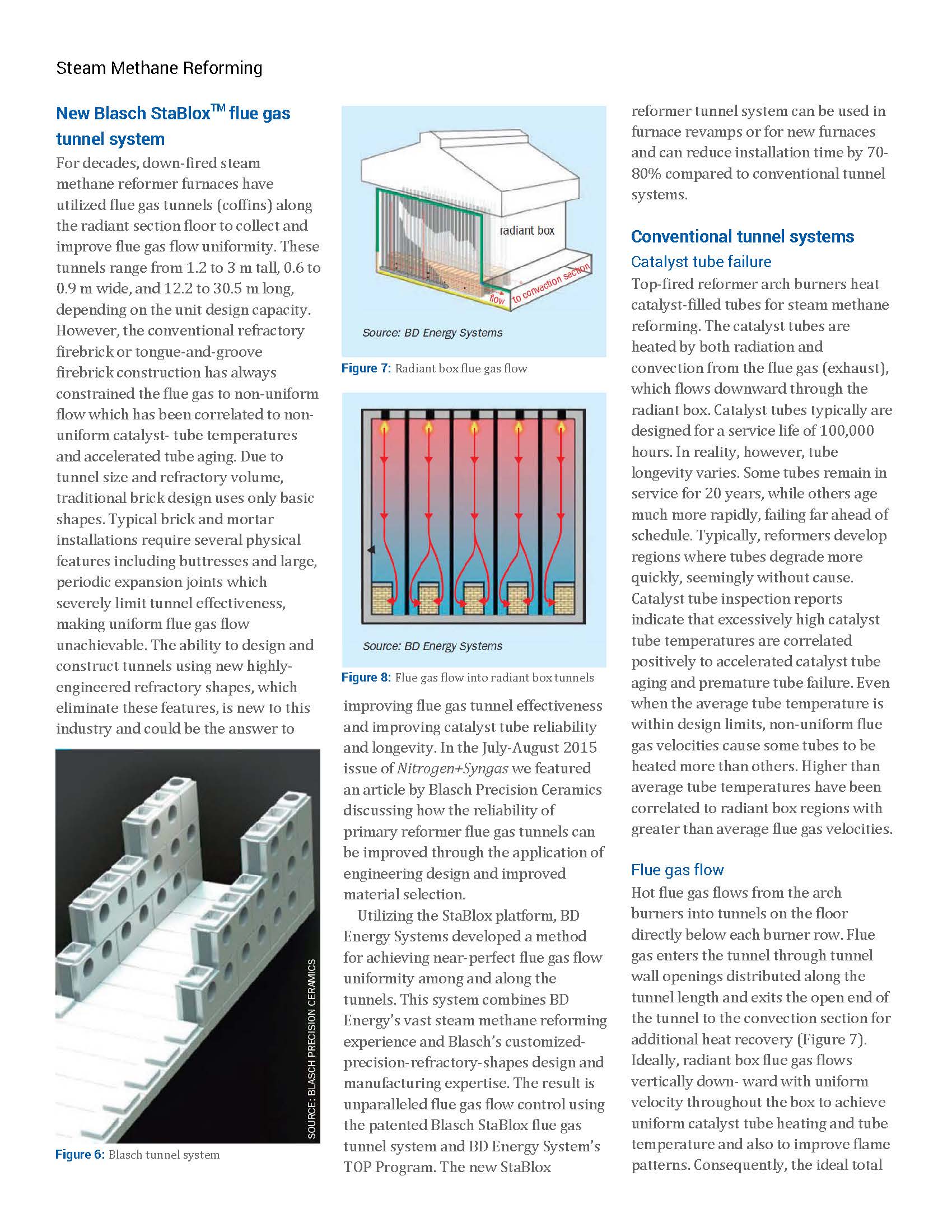

Traditionally, down-fired steam methane reformer furnaces have utilized flue gas tunnels along the radiant section floor to improve temperature uniformity. The requirements of typical brick and mortar installations severely limited tunnel effectiveness and made uniform flue gas flow unachievable.

Traditionally, down-fired steam methane reformer furnaces have utilized flue gas tunnels along the radiant section floor to improve temperature uniformity. The requirements of typical brick and mortar installations severely limited tunnel effectiveness and made uniform flue gas flow unachievable.

In July/August 2016 issue of N+S, Ceramic Product China Inc. describes how it achieved near-perfect flue gas flow uniformity among and along tunnels with cutting edge StaBlox technology and BD Energy Systems TOP Technology. With it, plants experience:

Register to download this article and learn more about the advantages of StaBlox.